If there’s one thing we know that everyone wants from their seed machinery, it’s precise cleaning and sorting. If your current machine isn’t doing the job, then it’s time to find another solution to your problem.

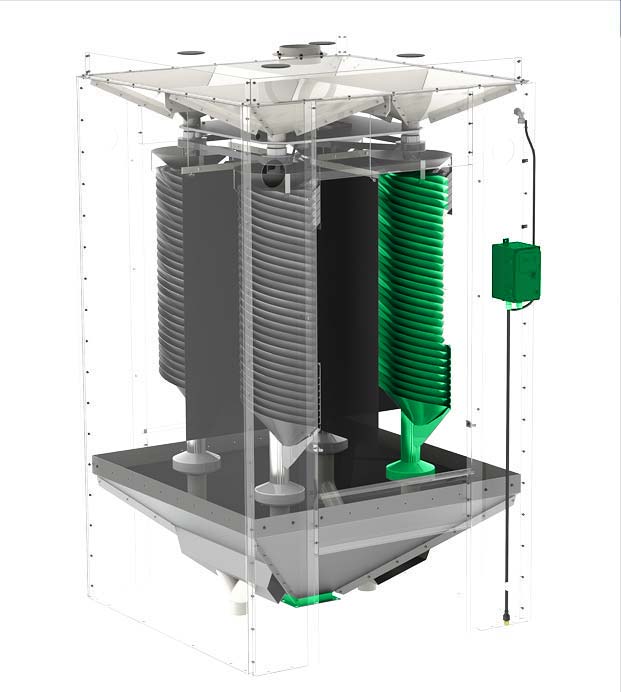

Spirals are great if there’s no power source in sight — they are non-power based, so there wouldn’t be any problem if your seed plant didn’t have another plug-in available. Because spirals are non-power based, they have stationary cores. They come in either open or closed units with a manual slide gate to control quality that can be adjusted for your convenience.

In comparison, rotary sorters are in a way an improvement from spiral separators. Rotary sorters work best if you want flexibility for fine, precise tuning using a VFD Drive.

With all of that information on the table, that’s when we like to bring our expertise to the forefront, allowing an easier decision for what works best for you and your product. The first thing we do when looking at what seed machinery you need is to assess your current issue. By looking at your unique situation, we can determine which machine would better fit your needs. Still can’t decide between the two pieces of equipment? Then we’d recommend keeping a few things in mind:

Questions to Consider When Making Your Decision on New Machinery:

The Turnover of your seed conditioning Operators

The experience level of your seed conditioning operators.

The current quantity of seed conditioned

If there’s one piece of advice we’d like to share, it’s that learning all you can about the products before making an investment is key.

We will spend the time learning about your operation and make our recommendations on the best route to take.

⊗ Non-Power Based

⊗ Manual Slide Gate Adjustment

Spiral

vs.

Sorter

What’s the Difference?

⊕ VFD Rotating Cores

⊕ Push Button PLC Flexability